SAP QM Vendor-end Quality Inspection Process

SAP QM Vendor-end Quality Inspection Process

I would like to share one of quality inspection scenario I have mapped.

Business Scenario :

a, business involved in Panel manufacturing process with MTO scenario where panel components are supplied to subcontractor and after completion of assembly at subcontractor end.

b, subcontractor inform to buyer for Quality Inspection, buyer inform to Quality engineer that assembly is ready for quality inspection.

c, after completion of quality inspection at vendor location. Quality engineer give clearance to subcontractor for delivery of goods at factory.

d, Quality report are prepared manually and informed to buyer and store manager. On receipt of assembly at factory, final Inspection of assembly is completed.

Challenges in current process:

1.Defect occur at vendor end inspection cannot be captured.

2.Reason for defect happened during inspection not available.

3.Number of Inspection held at vendor-end not available.

4.Reason for delay not captured either by subcontractor or by Quality engineer or by buyer.

5.Cost of Quality Inspection cannot be identified.

SAP Solution:

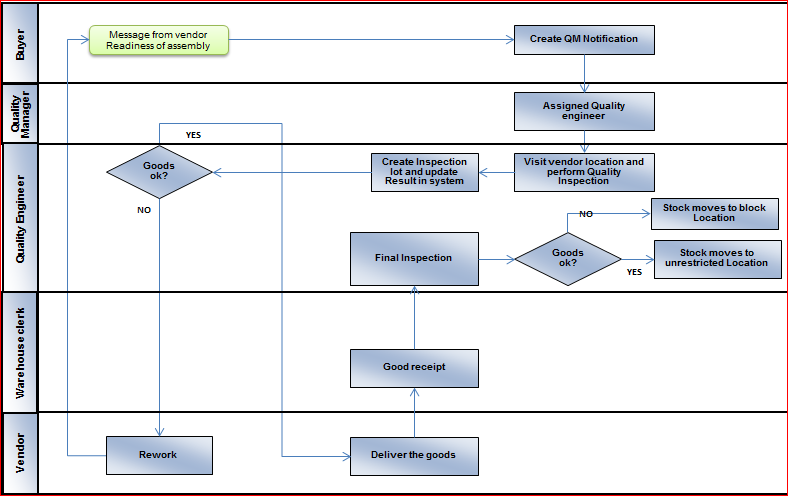

- Assembly material Master should be updated with Inspection type 89 -other inspection.

- On receipt of message from subcontractor to Buyer for readiness of assembly. buyer to create Internal problem QM notification.

- Send email to Quality engineer through Quality notification change screen.

- Quality engineer visit vendor location and perform Quality Inspection of assembly as per check list and update result to vendor and buyer.

- Quality engineer has to create Inspection lot against QM notification and update result against it as per vendor end Quality report.

- Quality report is scan and attached to document through DMS.

- In case of defect during Inspection, rework will be done by vendor and re-inspection for same assembly will be captured by different QM notification.

- Final Inspection will be done on goods receipt against Purchase order.

- Accepted assembly moves to unrestricted use and rejected will be moves to block stock.

Process-flow-chart for vendor end Inspection

Advantages of mapping vendor-end-inspection in SAP.

1.Defect appearing in vendor-end-inspection available for quality analysis.

2.Reason for delay is identified and corrective action taken for it, to have on time delivery to customer.

3.Number of re-inspection are captured which help in corrective action.

4.Cost of Inspection can be identified.

I hope scenario discuss herewith will be helpful to you.

Thanks

https://blogs.sap.com/2015/04/17/vendor-end-quality-inspection-process/

还没有评论,来说两句吧...